Continuous improvement

The behaviour of liquid metal and the solidification process play a fundamental role in the effectiveness and efficiency of the production process. S.A.V. S.p.A. is able to support customers with comparative analysis between different alloys by comparing:

• metal fluidity;

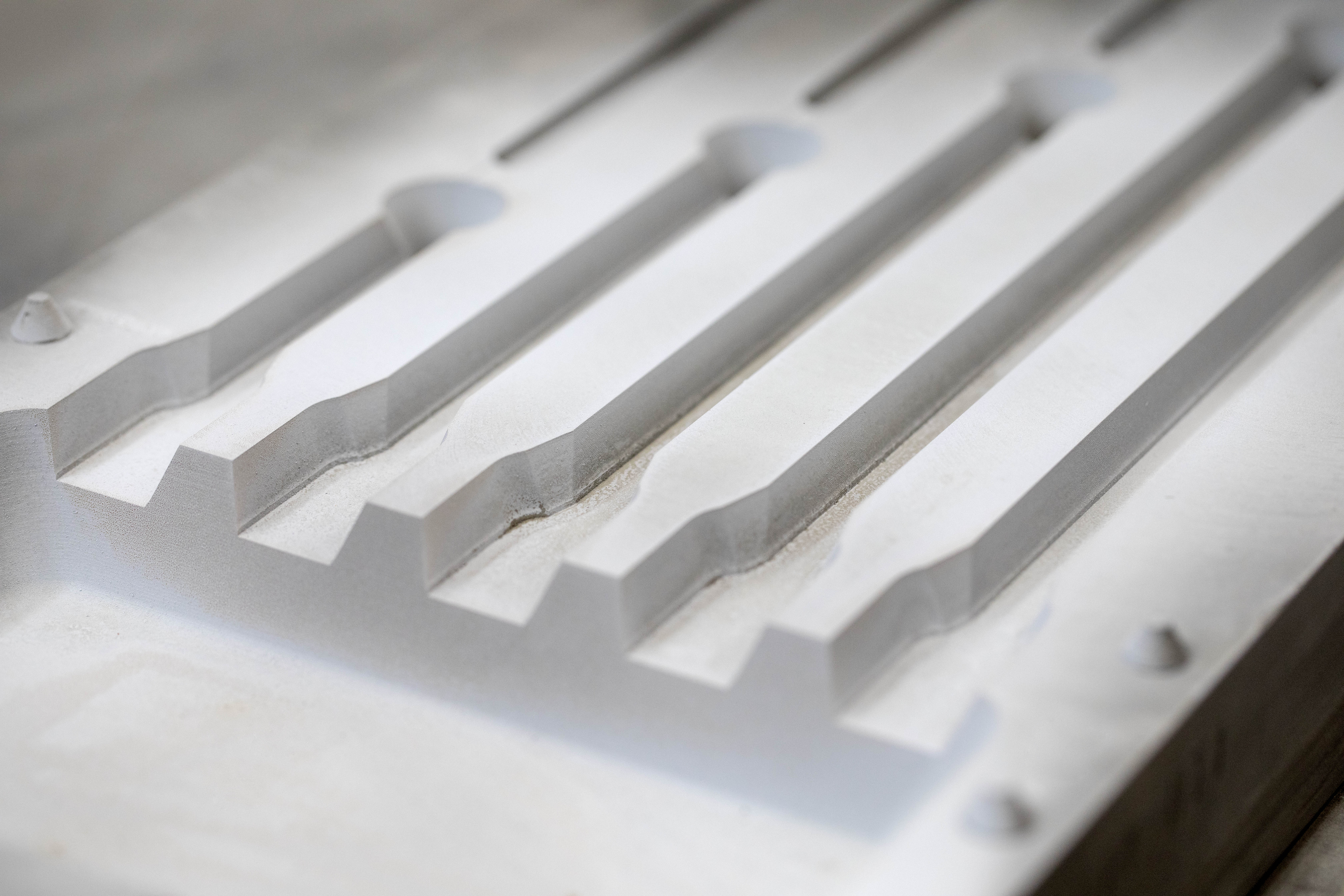

• metal casting shrinkage during the solidification phase;

• hot tearing of aluminium alloys.

In this way it is possible to improve the chemical-physical properties of the alloy so as to increase the efficiency of the production process minimizing the casting defects and, consequently, the production waste.

The improvement of production processes also implies the optimization of heat treatment which allows to obtain castings with the required mechanical properties.

S.A.V. S.p.A. disposes of heat treatment ventilated ovens for the simulation, with laboratory tests, of the solubilization and aging process of aluminium alloys. The ovens allow to carry out tests with any temperature and time ramp, even in controlled cooling.

Moreover, it is also possible to determine the temperature effects of quenching medium on the final mechanical properties of the aluminium alloy.

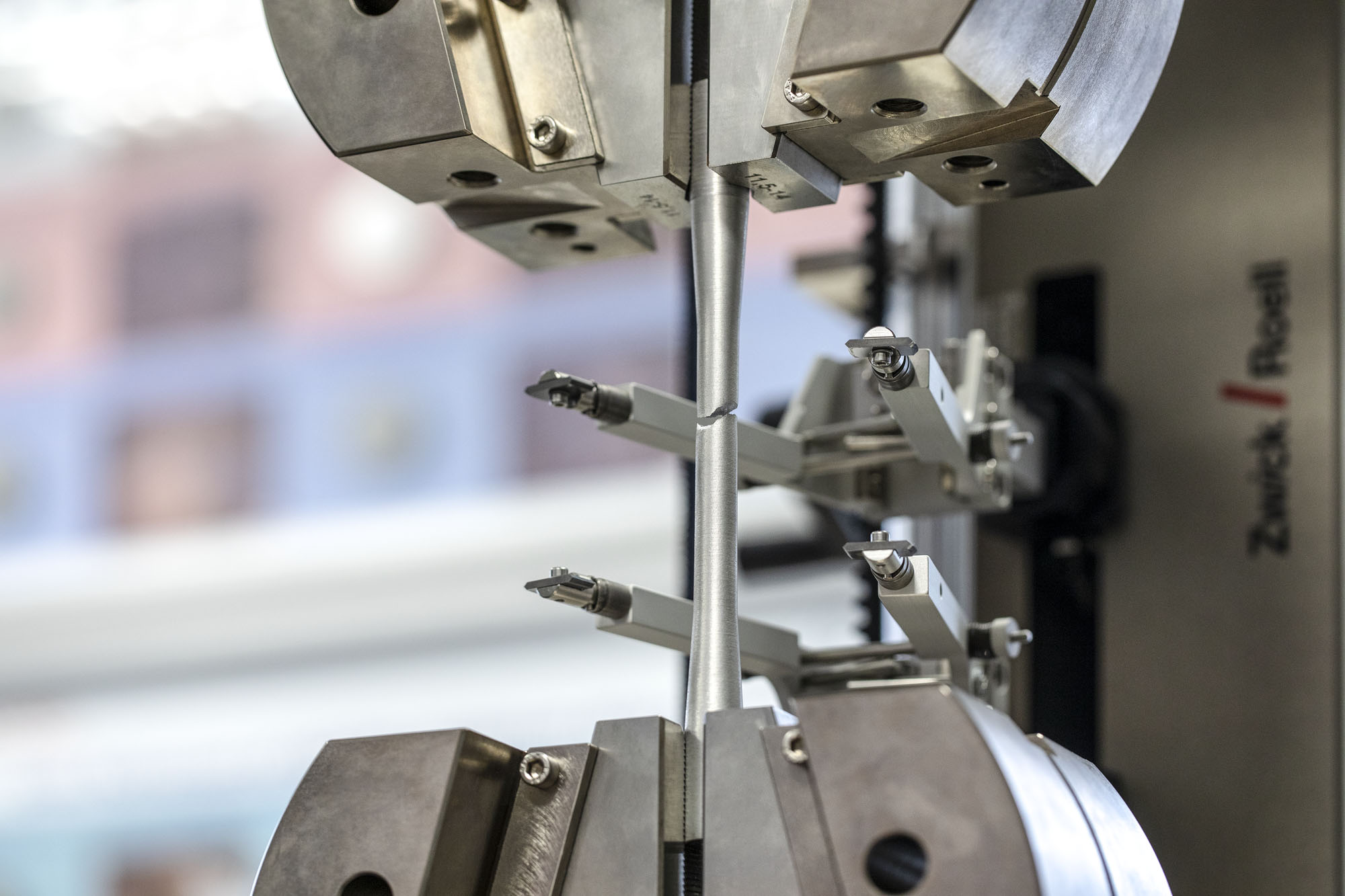

Furthermore, mechanical properties such as elastic modulus, elongation, yield strength and breakage are determined by cold tests according to ISO 6892 part 1 and ASTM E8 / E8M.

The measurement of the elastic modulus, elongation, yield strength and tensile strength of alloys also takes place with tests carried out at high temperature in compliance with ISO 6892 part 2.

Finally, hardness is determined in compliance with ISO 6506-1 and ASTM E10 standard.