The chemical-physical characterization of aluminium alloys and of castings produced by the customer

The internal metallurgical laboratory is able to carry out the following characterizations on aluminium alloys:

• determination of the chemical composition by spark-oes spectrometry;

• determination of metal density ;

• determination of density index;

• determination of the solidus and liquidus temperature through the thermal analysis technique (solidification curve);

• determination of metallic inclusion level through the Prefil technique;

• quantitative determination of non-metallic inclusions by analysis of Prefil filters (with automatically generated reports highlighting the inclusions detected by the filter analysis);

• determination of hydrogen dissolved in liquid aluminium using the Al-Scan technique;

• measurement of electrical conductivity;

• measurement of thermal conductivity;

• determination of the specific heat of the alloy;

• determination of Brinnel hardness in compliance with ISO 6506-1 and ASTM E10;

• determination of the mechanical properties at room temperature of the aluminium alloys: elastic modulus, yield strength, tensile strength and elongation in compliance with ISO 6892-1 and ASTM E8 / E8M standards;

• determination of the high temperature mechanical properties of aluminium alloys: elastic modulus, yield strength, tensile strength and elongation in compliance with ISO 6892-2 and ASTM E8 / E8M standards.

Morever, the following characterizations are carried out on the aluminium alloy castings:

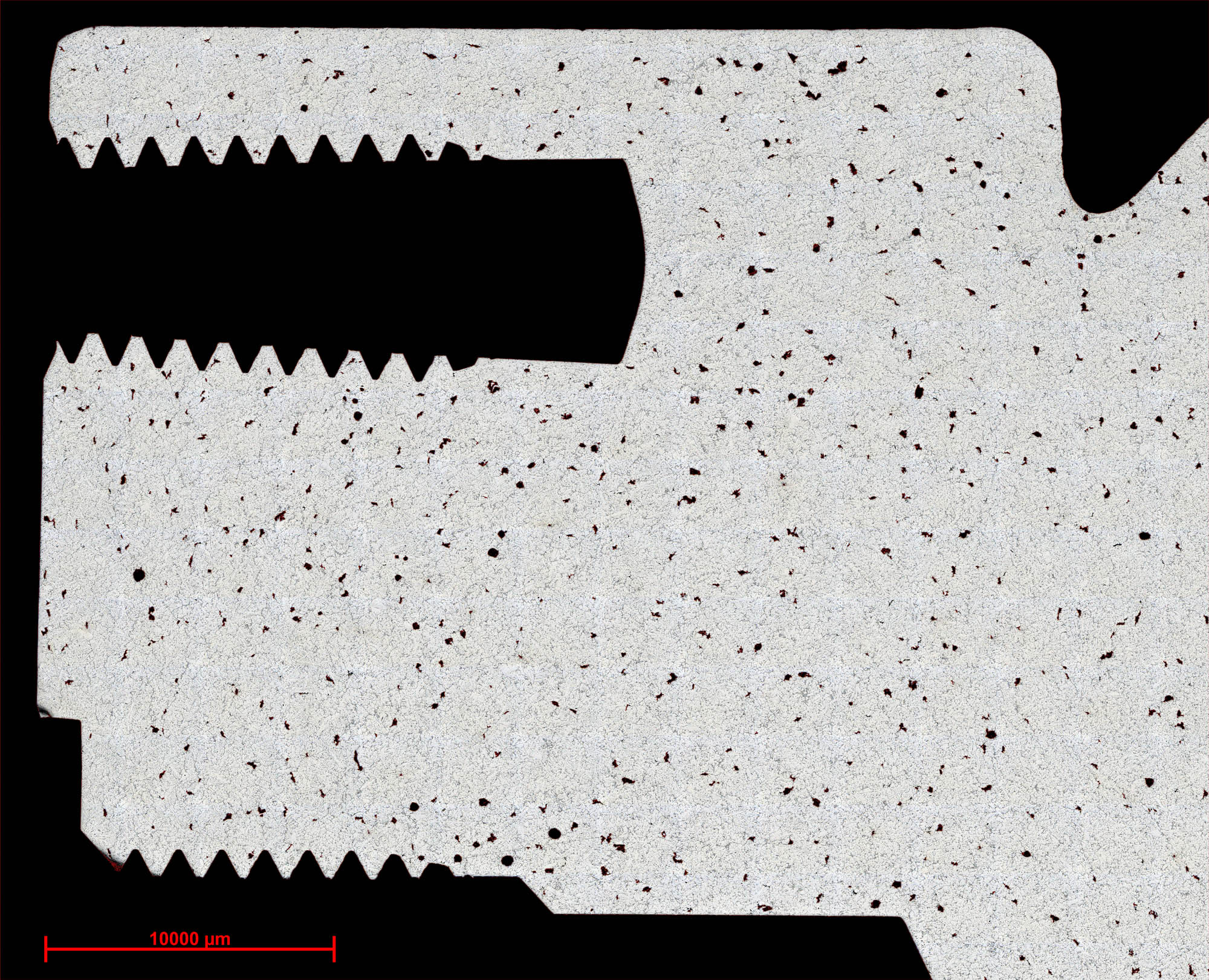

• metallography by optical microscopy;

• determination of intermetallic phases dimensions through optical microscopy;

• determination of DAS (Dendrite Arm Spacing) and SDAS (Secondary Dendrite Arm Spacing);

• determination of the grain size;

• determination of the geometric parameters of the intermetallic phases through optical microscopy;

• classification of casting defects by analysis at optical microscope;

• mapping porosity in the castings through optical microscope with motorized table;

• quantification of the percentage of porosity present in the castings using an optical motorized stage microscope.